Features

- Suitable for metal-metal and plastic-metal threaded connections

- Drinking water approval for quality water applications

- No dirt with its non-dripping formulation

- Keeps its sealing properties against shocks & vibrations long after the application

- Provide enhanced resistance to many chemicals with its advanced formulation

Application

- Close-fitting metal pipe threads where all kinds of water, oil, grease, and many chemicals pass

- Pressure vessels

- Air compressors

- Hydraulic systems and tanks

- Areas where resistance against vibration is required

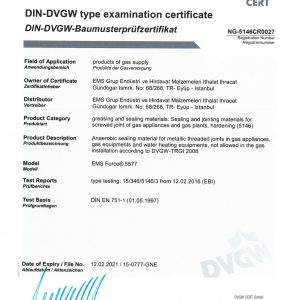

- Suitable for Type H thick metal thread joints according to TSE EN 751-1 Standard.

Usage and Instructions

Surface Preparation

- Ensure parts are clean, dry and free from oil and grease.

- Applied with a brush or directly from tube.

Application

- Apply the adhesive with a 360 turn to leading threads of the male and female fittings.

- Use an absorbent tissue paper to wipe off excess jointing compound in the direction of the thread.

- Assembly parts and hold on for 24 hours at 22-24°C to ensure full curing of jointing compound.

- For disassembly, use hand tools to remove mating parts.

- When it is hard to dissemble at room temperature, apply local heat until reaching 250°C and disassemble while hot. Then, remove any residual cured adhesive mechanically and clean parts with a proper solvent, acetone.

Technical Details

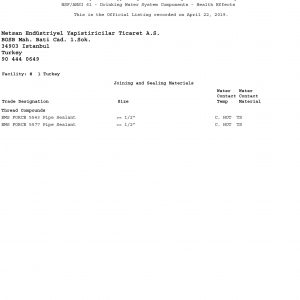

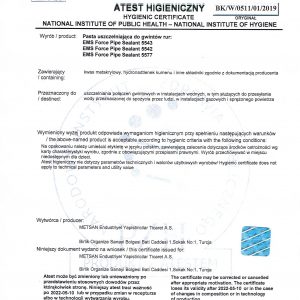

- Approvals: NSF, WRAS, DVGW, TSE, AGA

- Average handling time: 10 minutes (Conditions: 22°C)

- Classification: Class III (AGA approval classification)

- Colour: Yellow

- Corrosive: Non-corrosive

- Flash Point: >93°C

- Gap Filling: Up to 0.5mm

- Maximum Rating Pressure: 2000kPa (20bar) AGA approved

- Shelf Life: 24 months Under recommended conditions

- Specific Gravity: 1.02

- Temperature range: -10°C to 150°C

- Viscosity: 50000 – 60000 cP (Conditions: 22°C Method: ISO 2555 Apparatus: Brookfield RVT, spindle 6)