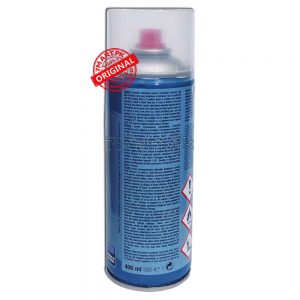

Why CRC Power Contact Cleaner is Important ?

Features :

• No ozone depleting action.

• Does not leave a residue.

• Non corrosive.

• Non conductive.

• Safe on all metal surfaces, does not stain.

• Safe on most rubbers, plastics and coatings. Test on sensitive or stressed materials before use.

• Convenient 360° (including inverted position) spray valve for aerosols.

• High purity CO2 propellant, giving an active product content of 95%.

Applications :

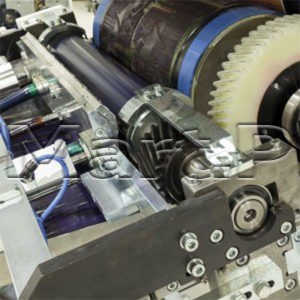

• Fast cleaning action for removal of flux traces, light oils, finger prints and other contaminants.

• Electro-mechanical assemblies.

• Control assemblies.

• All electrical contacts.

• Electronic components.

• Printed circuit boards.

• Sensors.

Directions :

• Spray liberally and allow to run off.

• Use extension tube for more precise application.

• Use only with adequate ventilation.

• Test before use on sensitive materials.

• Do not use on energized equipment.

• Do not use on sensitive electronic equipment.

• Allow to dry completely before reactivation. Protect and re-lubricate if necessary.

• To remove oxide and carbon deposits, use an abrasive and rinse off intermittently with CRC Contact Cleaner.

• A safety data sheet (MSDS) according to EC Regulation N° 1907/2006 Art.31 and amendments is available

for all CRC products.

Typical product data (without propellant) for CRC Power Contact cleaner

Appearance <br

Liquid.

Color

Colorless.

Density

0.677 g/cm3 (@ 20°C).

Flash Point

– 26 °C

Auto Ignition temperature

> 200 °C

Vapor density